Industrial Axial Flow Fans

Perkins Blowers Co. is a leading manufacturer of industrial axial flow fans in India. With over two decades of experience (since 2002) in ventilation equipment, Perkins designs fans covering a wide range of air volumes and pressures. Its axial fans use lightweight, cast-aluminum aerofoil impellers and high-efficiency blades to optimize airflow while keeping power consumption lowperkinsblowers.com. This makes them ideal for both routine plant ventilation and demanding industrial exhaust or cooling applications. Recognized as a top axial fan manufacturer in India, Perkins offers durable, high-performance fans built with strict quality controls and advanced production methods.

Perkins axial flow fans are engineered for maximum efficiency. Each fan features a precision-designed aerofoil-section impeller made of corrosion-resistant aluminum alloy. The blade profiles are tuned to balance airflow, pressure, and energy use, ensuring smooth, efficient operation. In fact, Perkins’ latest Energy-Efficient Series of axial fans uses adjustable-pitch blades (10–40°) made of aluminum or GRP to save up to 10% energy compared to conventional fans.

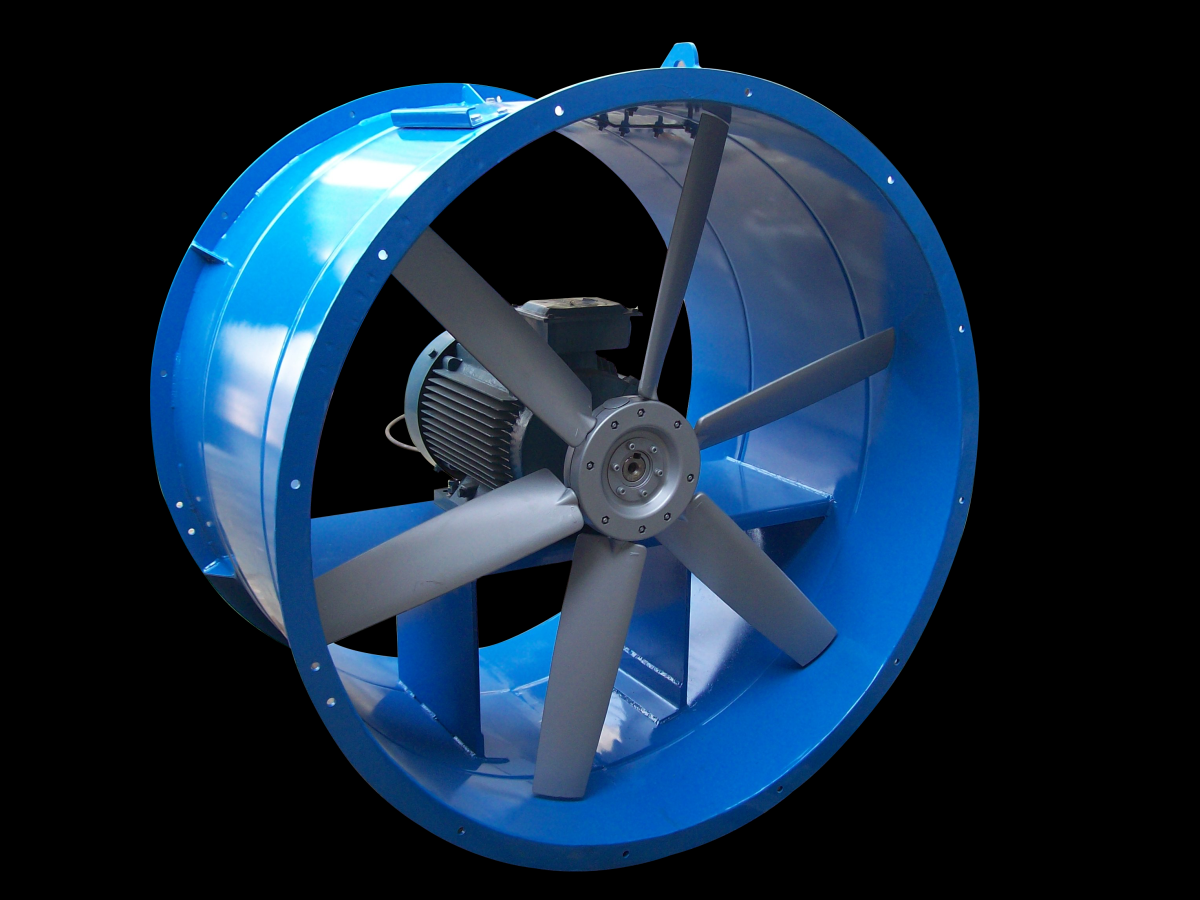

Vane Axial Fans with Aluminum Blades

Vane Axial Fan equipped with high-performance aluminum blades in a Direct Driven configuration. Ideal for robust industrial ventilation and exhaust applications.

| Business Type | Manufacturer, Exporter, Supplier |

| Driven Type | Electric |

| Application | Industrial |

| Warranty | 1year |

| Country of Origin | India |

| Blade Material | Stainless Steel, Plastic, Cast Iron |

| Power | 0.25 HP TO 100 HP |

| Capacity(Air Volume) | 900 CFM To 125000 CFM |

Applications:

-

Textile Humidification Systems

-

Captive Power Plant Ventilation

-

Generator Enclosure Cooling

-

Supply Air Distribution

-

Exhaust and Ventilation Systems

Vane Axial Fan with GRP Blades

Vane Axial Fan featuring GRP Blades (Energy Efficient Series) in a Direct Driven arrangement. Commonly used for general-purpose ventilation and exhaust applications.

| Business Type | Manufacturer, Exporter, Supplier |

| Driven Type | Electric |

| Color | Blue |

| Country of Origin | India |

| Capacity | 900 CFM To 125000 CFM |

| Impeller Size | 10 Inches to 82 Inches |

| Power | 0.25 HP To 100HP |

| Fan Speed | 960 RPM TO 2800 RPM |

Applications:

-

Generator Canopies

-

Exhaust Air Axial Flow Fan

-

Roof Extractor

-

Booster Fan for In-Line Ducts

Bifurcating Fan

Bifurcating Fan with Aluminum or GRP Blades. Typically used for handling high-temperature and dusty air or fumes. The drive motor receives ventilation from a separate chamber (usually open to atmosphere), keeping it isolated from the process air. The air is ducted on both ends of the fan and flows without coming into contact with the electric motor. A reduction in efficiency of approximately 25% should be considered for such configurations.

| Business Type | Manufacturer, Exporter, Supplier |

| Driven Type | Electric |

| Country of Origin | India |

| Blade Material | SS,Cast Iron |

| Fan Speed | 960 RPM To 2800 RPM |

| Power | 0.25 HP To 100.0 HP |

| Impeller Size | 10 Inches To 82 Inches |

| Capacity | 900 CFM To 125000 CFM |

Vane Axial Indirect Driven Fan

Vane Axial Fan with Aluminum or GRP Blades in an Indirect Driven arrangement (V-Belt driven). Commonly used for handling high-temperature and dusty air or fumes.

All impellers are available in a wide range of diameters and blade counts to suit a variety of application needs. Each impeller is statically and dynamically balanced on a microprocessor-controlled computerized machine, in accordance with IS-1940 balance quality grade G-6.3.

| Business Type | Manufacturer, Exporter, Supplier |

| Driven Type | Indirect |

| Color | On Demand |

| Power | 1-3kw |

| Certification | CE Certified |

| Warranty | 1Year |

| Country of Origin | India |

| Brand Name | Perkins Blowers Co. |

Read more Centrifugal Fan Manufacturer in India