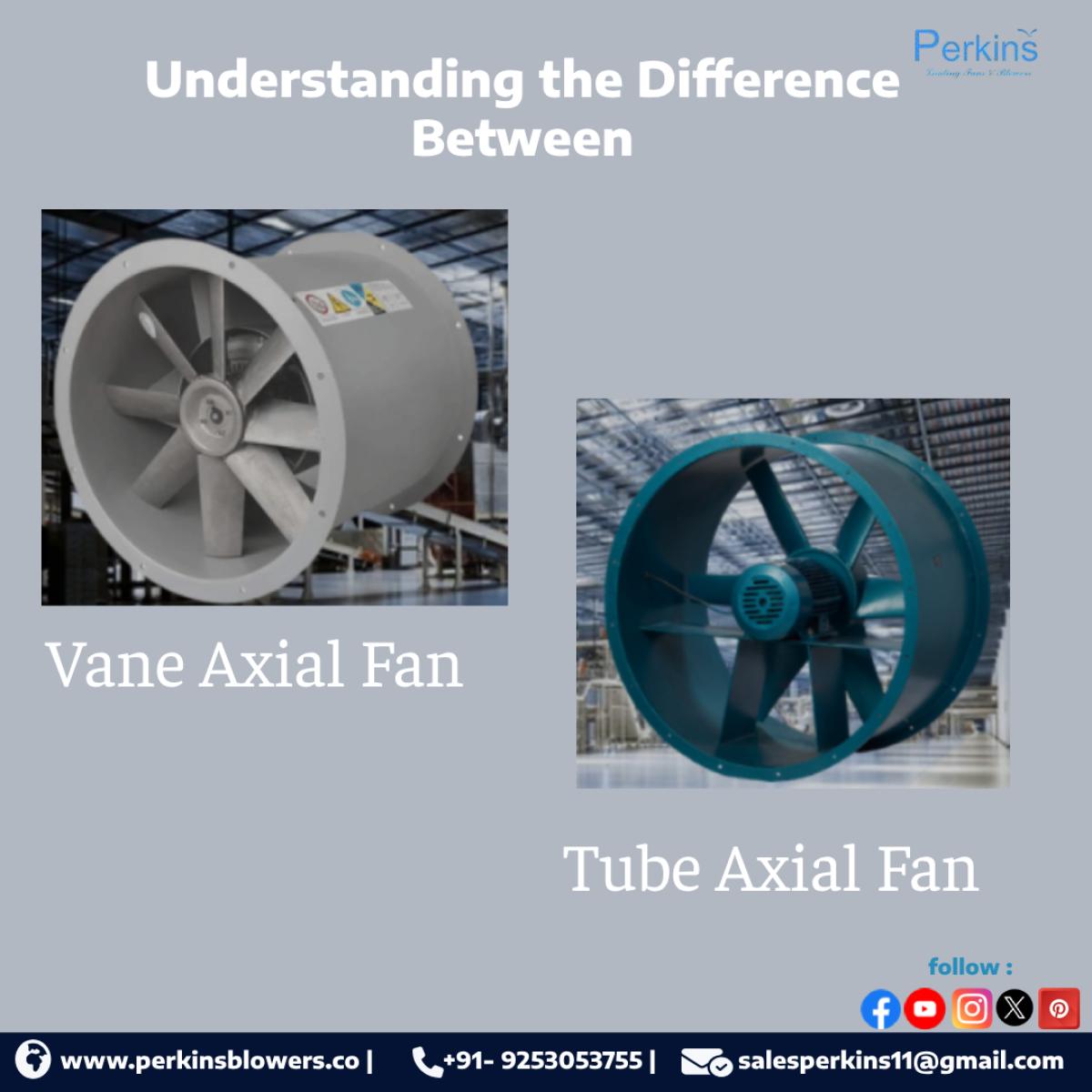

When it comes to industrial ventilation and air movement, axial fans are a critical component across many applications. At Perkins Blowers, a trusted name in the air handling industry, we often help our customers choose between different types of axial fans based on their performance requirements. Two of the most commonly used axial fan types are vane axial fans and tube axial fans. While they may appear similar in design, they differ significantly in terms of construction, airflow characteristics, efficiency, and use-case scenarios. In this blog, we will break down the key differences to help you make the right choice for your application.

A tube axial fan is the more basic version of the two and consists of a propeller mounted within a cylindrical housing (or tube). This fan is primarily designed for moving large volumes of air at relatively low pressure. The air flows parallel to the shaft in a straight line, making tube axial fans highly suitable for general ventilation tasks such as exhausting fumes, supplying fresh air, or cooling machinery in confined spaces. Because of their simple design, they are more cost-effective and easier to install, making them ideal for light to medium-duty applications.

On the other hand, a vane axial fan incorporates straightening vanes (also known as guide vanes) either before or after the fan blades within the cylindrical housing. These vanes are the defining feature and serve to straighten and direct the airflow, reducing turbulence and improving the fan’s overall aerodynamic efficiency. This results in higher pressure capabilities and more precise airflow control compared to tube axial fans. Vane axial fans are often used in demanding environments such as HVAC systems in large buildings, tunnels, ships, and industrial exhausts, where consistent and high-pressure airflow is required.

In terms of performance, vane axial fans offer higher efficiency and pressure but come at a higher cost due to their more complex construction. They are also more compact than centrifugal fans when pressure requirements are moderate, which is a benefit in space-constrained settings. Conversely, tube axial fans are valued for their lower initial investment, ease of maintenance, and adequate performance in simpler applications where high pressure or exact airflow control is not a priority.

Perkins Blowers designs and manufactures both vane axial and tube axial fans with precision engineering and industry-grade materials to ensure long-lasting performance. Whether you're working in manufacturing, mining, agriculture, or HVAC systems, understanding the functional differences between these two types of fans is essential for optimizing energy consumption, ensuring operational efficiency, and minimizing maintenance needs.

In conclusion, the choice between a vane axial fan and a tube axial fan depends on your specific airflow demands and operational conditions. If you require cost-effective air movement for general ventilation, a tube axial fan is likely the right choice. However, if your application calls for higher static pressure and directional airflow control, then investing in a vane axial fan will deliver better long-term results. At Perkins Blowers, our technical team is always ready to guide you through the selection process and offer customized solutions tailored to your project requirements.

Read more : Axial Fans Explained: The Science Behind Streamlined Airflow