In industrial operations, air quality is not just a regulatory concern—it’s a critical component of equipment longevity, worker safety, and overall productivity. Industries such as cement, steel, pharmaceuticals, and food processing generate significant dust and particulate matter during manufacturing processes. To effectively capture and control this airborne pollution, dust collectors are indispensable.

When paired with Forced Draft (FD) fans, dust collectors operate with enhanced efficiency, improved airflow, and greater energy control. At Perkins Blowers, a trusted name in industrial ventilation solutions, we specialize in manufacturing high-performance dust collectors integrated with FD fans—custom-engineered to meet diverse industrial applications.

What Is a Dust Collector with an FD Fan?

A dust collector is a system designed to capture, filter, and remove dust and other particulate matter from air or gas. The system typically includes filter bags, hoppers, a pulse-jet cleaning mechanism, and ductwork.

A Forced Draft (FD) fan, on the other hand, is a type of industrial fan that pushes air into the system under positive pressure. When used in conjunction with a dust collector, the FD fan drives air and dust-laden gases into the collector, ensuring consistent and high-volume airflow.

This combination ensures efficient removal of fine particles, reduces system resistance, and boosts the overall effectiveness of the dust collection unit.

Key Components of the System

1. Dust Collector Unit

-

Fabricated from robust materials (MS, SS)

-

Equipped with bag filters or cartridge filters

-

Hopper and discharge valve for collected dust

-

Pulse-jet cleaning for continuous operation

2. FD Fan (Forced Draft Fan)

-

Designed to provide high static pressure

-

Can be direct- or belt-driven

-

Typically installed at the system's inlet

-

Built with dynamically balanced impellers and high-efficiency motors

3. Ducting and Accessories

-

Precision-designed ducts for airflow optimization

-

Expansion joints, dampers, silencers, and vibration isolators

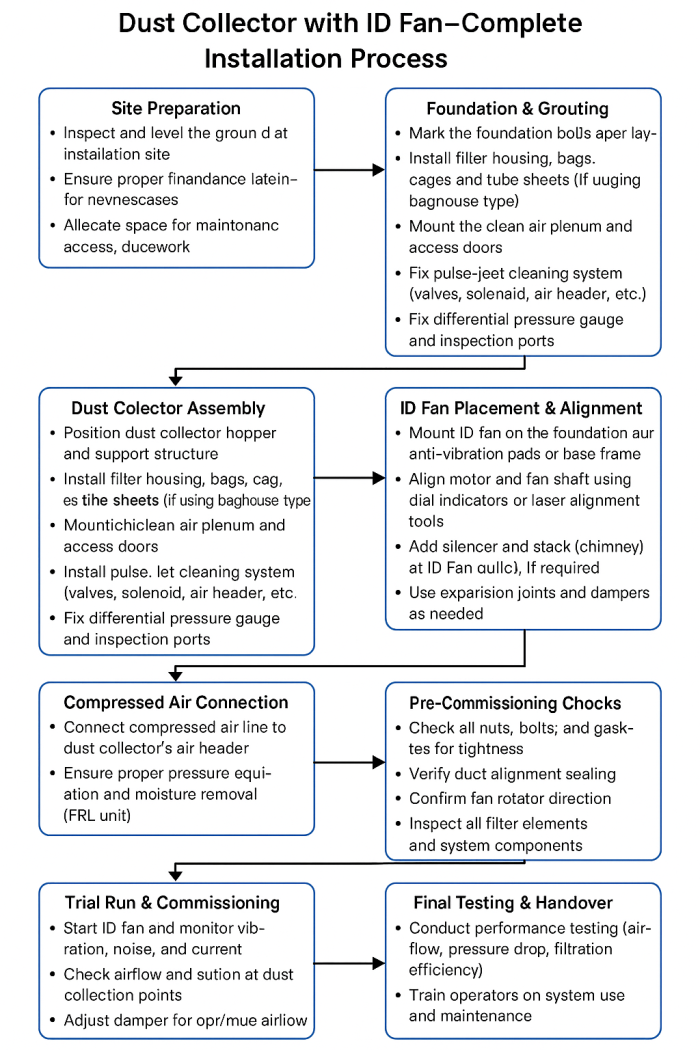

How the System Works

-

Air Intake:

The FD fan draws in ambient or process air and pushes it into the ductwork leading to the dust collector. -

Dust Collection:

Dust-laden air enters the collector’s inlet and is directed through filter bags or cartridges. -

Filtration:

Particles are trapped on the surface of the filters, while clean air passes through. -

Cleaning Cycle:

A pulse-jet mechanism periodically releases compressed air to dislodge accumulated dust from the filter surfaces. -

Dust Disposal:

Collected dust settles in the hopper and is removed through manual or automatic discharge valves. -

Air Discharge:

The cleaned air is then either released into the atmosphere or recirculated, depending on the application.

Applications Across Industries

At Perkins Blowers, our dust collector systems with FD fans are tailored for a wide range of industrial sectors, including:

-

Cement Plants – Kiln and material handling dust control

-

Steel Industry – Furnace gas filtration

-

Pharmaceutical Units – Powder handling and tablet coating areas

-

Food Processing Plants – Grain dust and packaging operations

-

Chemical and Paint Industries – Pigment and fine powder management

-

Foundries – Sand and metal particulate filtration

Whether it's heavy dust or fine powder, our systems are engineered to tackle every type of airborne contaminant.

Why Choose Perkins Blowers?

Customized Engineering

Every industrial setup has unique airflow and dust characteristics. Perkins Blowers offers complete system customization—from fan design to dust collector sizing—to match your specific process needs.

High-Efficiency Fans

Our FD fans are manufactured using dynamically balanced impellers, high-efficiency motors, and precision-aligned shafts for maximum energy savings and long service life

Quality Assurance

We use high-grade raw materials, follow strict fabrication standards, and test each unit for vibration, pressure, and airflow before dispatch.

On-Site Installation & Support

Our expert technicians handle full system installation, commissioning, and training. We ensure a smooth handover with on-site testing and documentation.

After-Sales Service

Perkins Blowers provides reliable after-sales service, filter replacement, AMC packages, and technical support for ongoing performance.

Advantages of Using Dust Collector with FD Fans

-

Improved Suction & Filtration Efficiency

FD fans ensure positive pressure airflow, helping maintain uniform dust capture across multiple points. -

Lower Maintenance Downtime

Pulse-jet cleaning keeps filters clean and operating efficiently without frequent shutdowns. -

Compact Design

Our integrated systems save floor space while delivering high capacity. -

Energy Efficient Operation

Optimized fan curves and motor selection ensure minimal energy wastage. -

Compliance with Air Quality Norms

Ensures your operations meet pollution control standards (CPCB/ISO/OSHA-compliant designs).

Conclusion

Clean air isn’t a luxury—it’s a necessity in modern industrial processes. A Dust Collector with an FD Fan from Perkins Blowers offers a powerful, efficient, and sustainable solution to manage dust and airborne particulates.

Read more : Understanding the Three Common Types of Axial Fans: A Guide by Perkins Blowers