In the world of industrial fans and blowers, efficiency and performance are critical. One often overlooked factor that plays a significant role in fan operation is the motor insertion depth in the impeller. This engineering parameter, though subtle, can drastically impact airflow, energy consumption, noise levels, and overall system reliability.

In this blog, we’ll explore what motor insertion depth is, how it affects fan performance, and what best practices to follow when designing or configuring fans for optimal results.

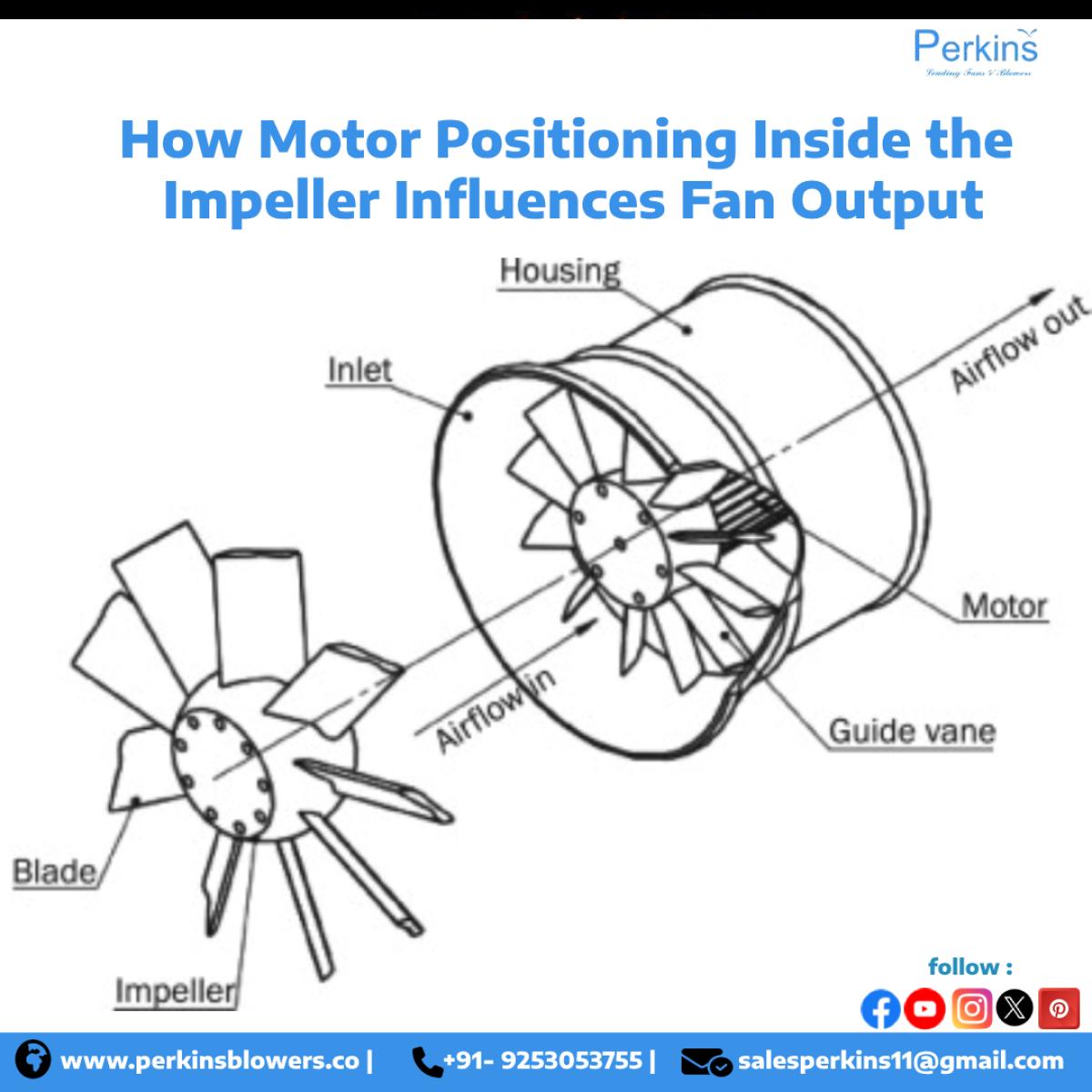

Understanding Motor Insertion Depth

Motor insertion depth refers to how far the motor shaft (and sometimes the motor body itself) extends into the impeller hub. The impeller, being the rotating part of the fan, is responsible for drawing in and expelling air. The position of the motor shaft within the impeller influences the fan’s mechanical balance, torque transmission, and air movement efficiency.

Insertion depth may vary depending on:

-

Fan design (axial, centrifugal, mixed flow)

-

Motor type (direct-drive, belt-driven)

-

Impeller size and structure

-

Application requirements

Key Ways Motor Insertion Depth Affects Fan Performance

1. Airflow Efficiency

A well-optimized insertion depth ensures that the impeller blades receive balanced mechanical input from the motor. If the motor is inserted too deeply or not deep enough:

-

Too deep: It can obstruct the internal airflow path, reducing the volume of air moved.

-

Too shallow: It may lead to insufficient torque transmission, causing unstable fan speed and reduced performance.

Proper insertion depth allows the impeller to rotate smoothly, maintaining consistent airflow and pressure.

2. Energy Consumption

When the motor is not optimally inserted, the fan system may require more energy to maintain the desired output. Misalignment or imbalance in the impeller leads to increased resistance, which the motor must overcome, thereby consuming more electricity.

Correct motor placement reduces friction and energy loss, helping industries meet energy efficiency goals.

3. Mechanical Stress and Vibration

Improper motor insertion depth can lead to unbalanced impeller rotation, causing:

-

Excessive vibration

-

Shaft bending or fatigue

-

Bearing wear

-

Reduced motor life

A balanced and correctly aligned motor-impeller setup minimizes mechanical stress, ensuring smooth and silent operation.

4. Noise Levels

Noise is a major concern in both commercial and industrial fan applications. Incorrect motor depth can result in uneven loading of the impeller blades, producing turbulence and mechanical hum or rattling.

Optimizing insertion depth helps maintain low sound levels, essential for noise-sensitive environments like HVAC systems in offices or hospitals.

5. Maintenance and Longevity

A poorly inserted motor leads to frequent breakdowns, necessitating costly maintenance. Proper shaft engagement reduces the risk of slippage, shaft misalignment, and early component failure, thereby extending the lifespan of the fan unit.

Best Practices for Motor Insertion Depth

To ensure peak fan performance:

-

Follow manufacturer guidelines: Always refer to technical datasheets and design manuals.

-

Use precise alignment tools: Laser alignment tools can help in achieving correct motor-to-impeller engagement.

-

Perform test runs: After assembly, run performance tests to detect any signs of imbalance or inefficiency.

-

motor-positioning-inside-the-impeller-influences-fan-outputConduct regular inspections: Preventive maintenance can catch any issues related to insertion depth before they escalate.

Conclusion

While motor insertion depth may seem like a minor mechanical detail, it has far-reaching implications on fan performance. From airflow output to energy consumption and system longevity, getting the motor position right is essential.

If you're involved in fan manufacturing, HVAC system design, or industrial ventilation, don’t underestimate the impact of this key design parameter. For customized ventilation solutions that prioritize precision and performance, trust manufacturers like Perkins Blowers, where every detail—from motor insertion to impeller design—is engineered for excellence.

Read more about What Are the Characteristics of Axial Fans?