In the world of industrial ventilation, especially when dealing with centrifugal and axial fans, understanding air pressure dynamics is crucial. Two important terms often encountered in fan performance data are static pressure and dynamic pressure. At Perkins Blowers, we believe in empowering our clients with technical knowledge to make informed decisions. This article breaks down the difference between static pressure and dynamic pressure and why both matter in industrial fan applications.

What Is Static Pressure?

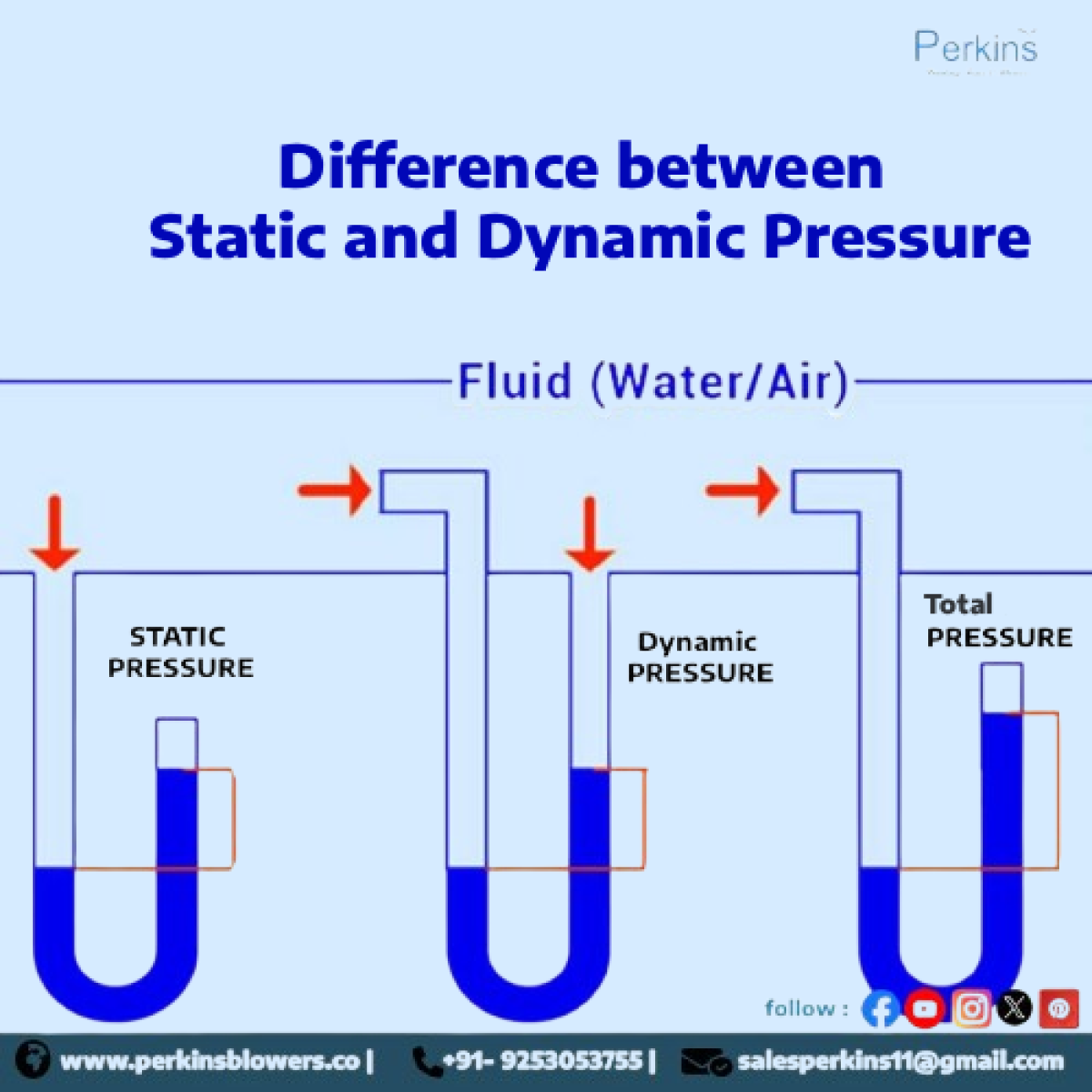

Static pressure is the pressure exerted by air that is not in motion. In the context of industrial blowers and fans, it is the force that pushes air through a system of ducts, filters, and other components. It resists the fan's airflow and must be overcome for the system to function efficiently.

Think of static pressure like the pressure you feel when you push air into a balloon. The balloon resists your effort, and that resistance is analogous to static pressure in a ventilation system.

Key characteristics:

-

Measured in inches of water column (in. wc) or Pascal (Pa)

-

Affects fan selection and duct sizing

-

Increases with longer duct runs, more filters, or system restrictions

What Is Dynamic Pressure?

Dynamic pressure refers to the pressure associated with moving air. It is the kinetic energy of the air as it moves through the system, and it increases with the square of the velocity. Dynamic pressure is not a resistance force like static pressure but rather a measure of how fast air is flowing.

You can compare it to the force of wind hitting your face when you run or ride a bike — that’s dynamic pressure in action.

Key characteristics:

-

Depends on air velocity and density

-

Related to the velocity pressure in fan performance curves

-

Expressed in the same units as static pressure (e.g., Pa or in. wc)

Total Pressure = Static Pressure + Dynamic Pressure

In fan systems, total pressure is the sum of static and dynamic pressure. It represents the total energy in the airflow and is used to determine overall system performance.

For example:

-

A high static pressure system might involve tight ductwork or multiple filters.

-

A high dynamic pressure system may involve fast-moving air through wide, open ducts.

Understanding the balance between static and dynamic pressure is key for engineers when selecting the right centrifugal or axial fan for a specific application.

Why This Matters for Industrial Fans

At Perkins Blowers, our team works with clients across India to design fans that match exact specifications. Misunderstanding these pressures can lead to:

-

Poor system performance

-

Excessive energy consumption

-

Noise issues

-

Premature wear of fan components

By accurately calculating static and dynamic pressures, we ensure the fans we supply deliver optimal airflow, energy efficiency, and long-term durability.

Conclusion

Whether you're designing a new ventilation system or upgrading an existing one, knowing the difference between static and dynamic pressure helps you select the right fan and system configuration. At Perkins Blowers, we combine technical expertise with high-quality industrial fans manufacturers to support your airflow needs with precision and reliability.

For expert guidance on industrial fan selection or custom-built solutions, contact Perkins Blowers – your trusted partner in air movement technology.