In industries where dust, wood chips, or fine particles are generated, keeping the workspace clean and maintaining air quality is crucial. One of the most efficient solutions is a cyclone dust collector. But what exactly is it, and how does it work? Let’s break it down in simple terms.

What is a Cyclone Dust Collector?

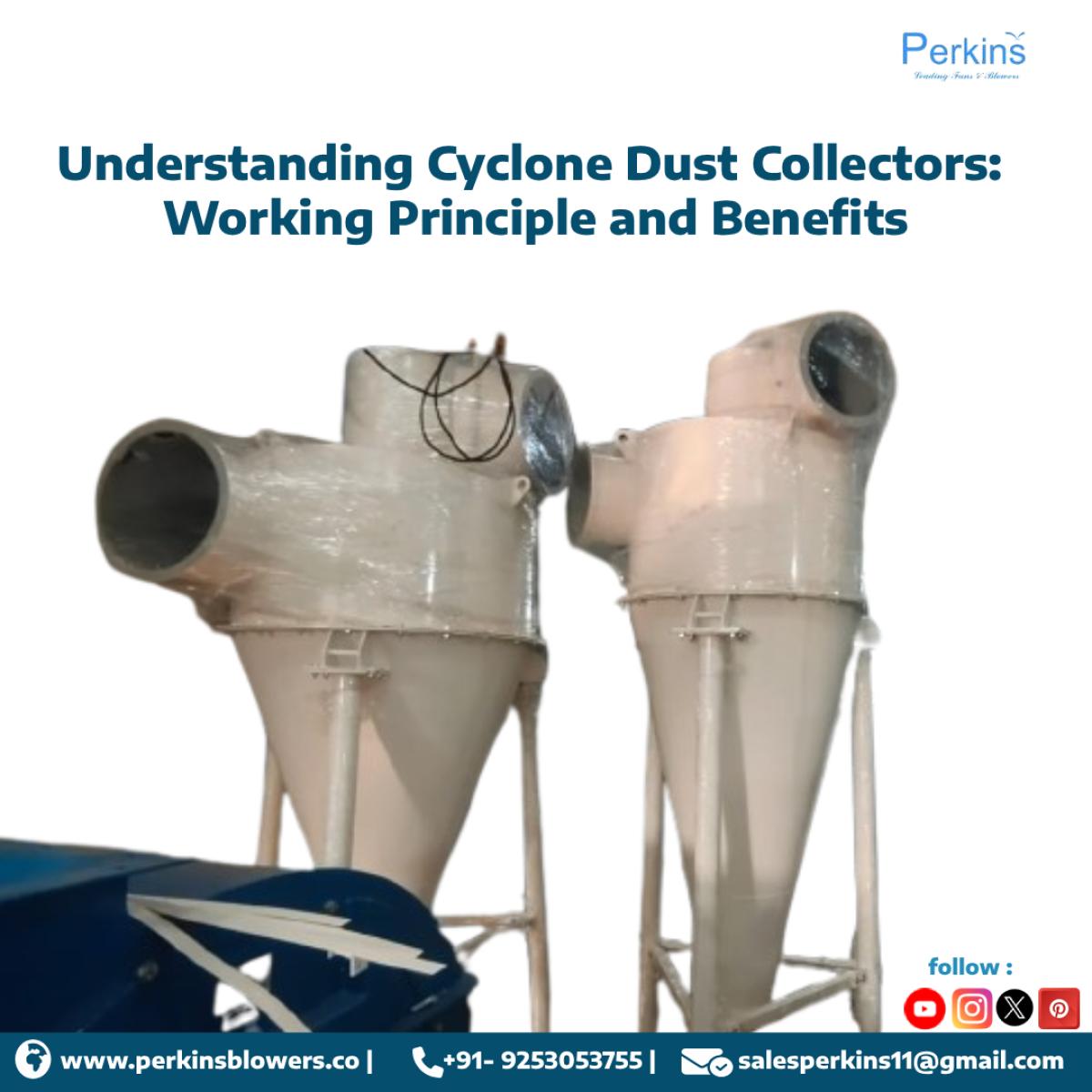

A cyclone dust collector is a type of air pollution control device designed to remove large and high-volume dust particles from an air stream. Unlike traditional filters that trap dust directly, cyclone collectors use the principle of centrifugal force to separate dust from the air.

They are widely used in woodworking, cement plants, steel industries, grain processing, and other industrial applications where dust control is critical.

How Does a Cyclone Dust Collector Work?

The working process can be explained in four simple steps:

1. Dust-Laden Air Enters the Cyclone

The air carrying dust and debris is sucked into the cyclone collector through an inlet. This air usually enters tangentially, creating a circular or spiral motion inside the unit.

2. Cyclonic Motion is Created

As the air spins at high speed, it creates a cyclone effect. Just like in a whirlpool or tornado, the heavier particles are forced outward against the walls of the cyclone due to centrifugal force.

3. Separation of Dust and Air

The heavier dust particles lose momentum, fall downward, and are collected at the bottom of the cyclone in a dust bin or hopper. Meanwhile, the lighter, cleaner air spirals upward through the center of the cyclone.

4. Clean Air is Released

Finally, the cleaned air exits through the outlet at the top, either back into the workspace or into an additional filtration system for finer particles.

Also read Essential Guide to Dust Collection Systems Maintenance: Focus on Cyclones and Filter Collectors

Advantages of a Cyclone Dust Collector

- Efficient for Large Particles: Ideal for wood chips, sawdust, and heavy dust.

- Low Maintenance: No moving parts and minimal filter replacement.

- Durable Design: Can withstand tough industrial environments.

- Energy Efficient: Uses natural air movement principles with low energy consumption.

- Cost-Effective Pre-Filter: Often used as a first-stage separator before bag filters or cartridge filters.

Limitations of Cyclone Dust Collectors

While they are excellent for large particles, cyclone dust collectors are less effective for very fine dust (like smoke or ultra-fine powders). For complete air purification, they are often paired with bag filters or HEPA filters.

Conclusion

A cyclone dust collector works on the principle of centrifugal force, spinning the air to separate dust and debris from the airflow. It’s a simple, cost-effective, and durable solution for industries dealing with large amounts of dust.

By installing a cyclone dust collector, businesses not only improve air quality but also protect machinery, enhance worker safety, and ensure compliance with environmental standards.

If you are looking for high-performance dust collection solutions, Perkins Blowers Co. offers durable and efficient cyclone dust collectors customized to your industrial needs.

Read more - EC Technology in HVAC: The Key to Energy Savings and Sustainability